Home > L series

L500 & L750

-

L500

Tandem drive - 2 Drive axles

GVWR: 65,000+ KG - (143,300+ lbs)

Power: 500KW - 670HP

Output Torque: 68,400 ft.lbs

Regen Power: 388KW - (520 HP)

Gross Axle Rating: 26,000 kg (57,400 lbs)

Suspension: Hendrickson Primaax XE

52,000 lb Capacity

Batteries: 175 kwh (diesel electric)

600 kwh (full electric)

Auxiliary Power: CAT C9- 350kw

Frame: 1/4” to 1/2” Grade 100 steel

9” to 12” web with 3-4” flange

lengths up to 48’ feet

Double and Triple Frame options available

Option power steer E-axle for 8x8 drive

Twin and Tri-steer option available

Top Speed - 130km/h (81 MPH)

-

L750

Tri-Drive - 3 Drive Axles

GVWR: 65,000+ KG - (143,300+ lbs)

Power: 750KW - (1005 HP)

Output Torque: 102,600 ft.lbs

Regen Power: 582KW - (780 HP)

Gross Axle Rating: 39,000 kg (86,100 lbs)

Suspension: Hendrickson Primaax XE

78,000 lbs capacity

Batteries: 280 kwh (Diesel-Electric)

600 kwh (Full Electric)

Auxiliary Power: CAT C9- 350kw

Frame: 1/4” to 1/2” Grade 100 steel

9” to 12” web with 3-4” flange

lengths up to 48’ feet

Double and Triple Frame options

Optional power steer E-axle for 8x8 drive

Twin and Tri-steer option available

Top Speed - 130km/h (81 MPH)

The toughest Electric truck ever made

the worlds first purpose built Heavy vocational electric truck

Built for Service

The easiest to maintain electric truck on the market today

The L series is designed to go into the places no other electric truck dares to, and it’s designed to haul more weight than any other electric truck while it does it.

These means from day 1 we designed the Edison truck to be easy to service in every aspect.

We consider all the small details. For example: not using huck bolts and using nuts to allow field service of parts. Huck bolts need a torch to remove, regular grade 8 bolts can use a wrench.

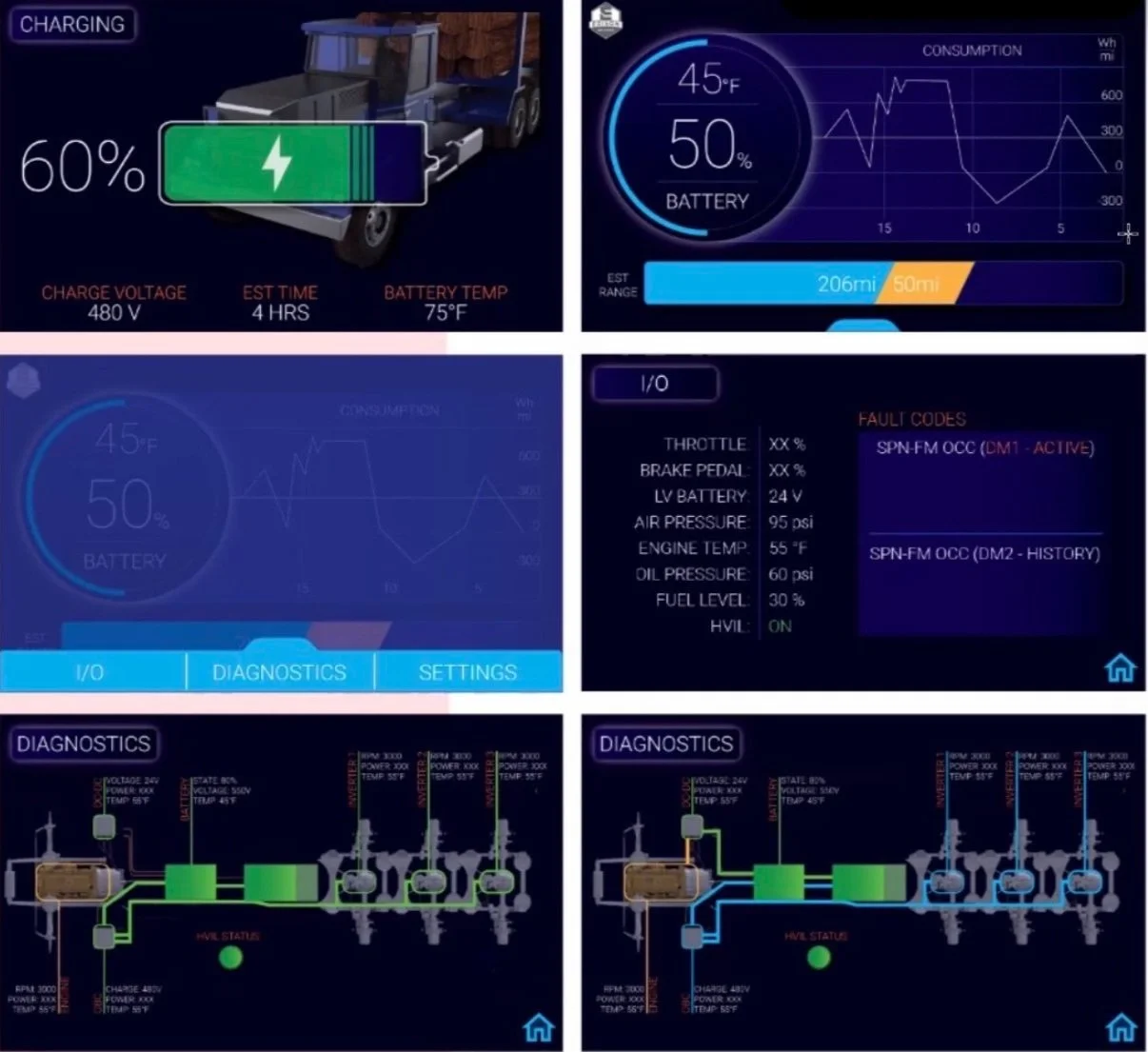

We consider the large things: We promise that no computer system we design will ever go into a dealership to have its code read, all fault codes will be available to the driver with a written description of the fault and trouble shooting hints when possible.

Every truck will come with a parts list of every single item put into the truck, what store we sourced that part from and the part number of the item. This makes sure that your mechanics can find the right part anytime they need.

If you’ll notice almost none of the parts used on these trucks are actually made by Edison. We use common parts available at any truck parts store like CBS, Fort Garry or Fleet Brake. This means you don’t have to rely on Edison service and parts department to send you items, you can get your truck fixed as soon as possible.

Edison intuitive EV control dashboard

Gives full truck information in realtime to the driver

The Dash consists of 2 LCD display screens that relay information in real time to the driver about exactly what the truck is doing. These screens are all fully customizable by the driver.

Operator safety is built in

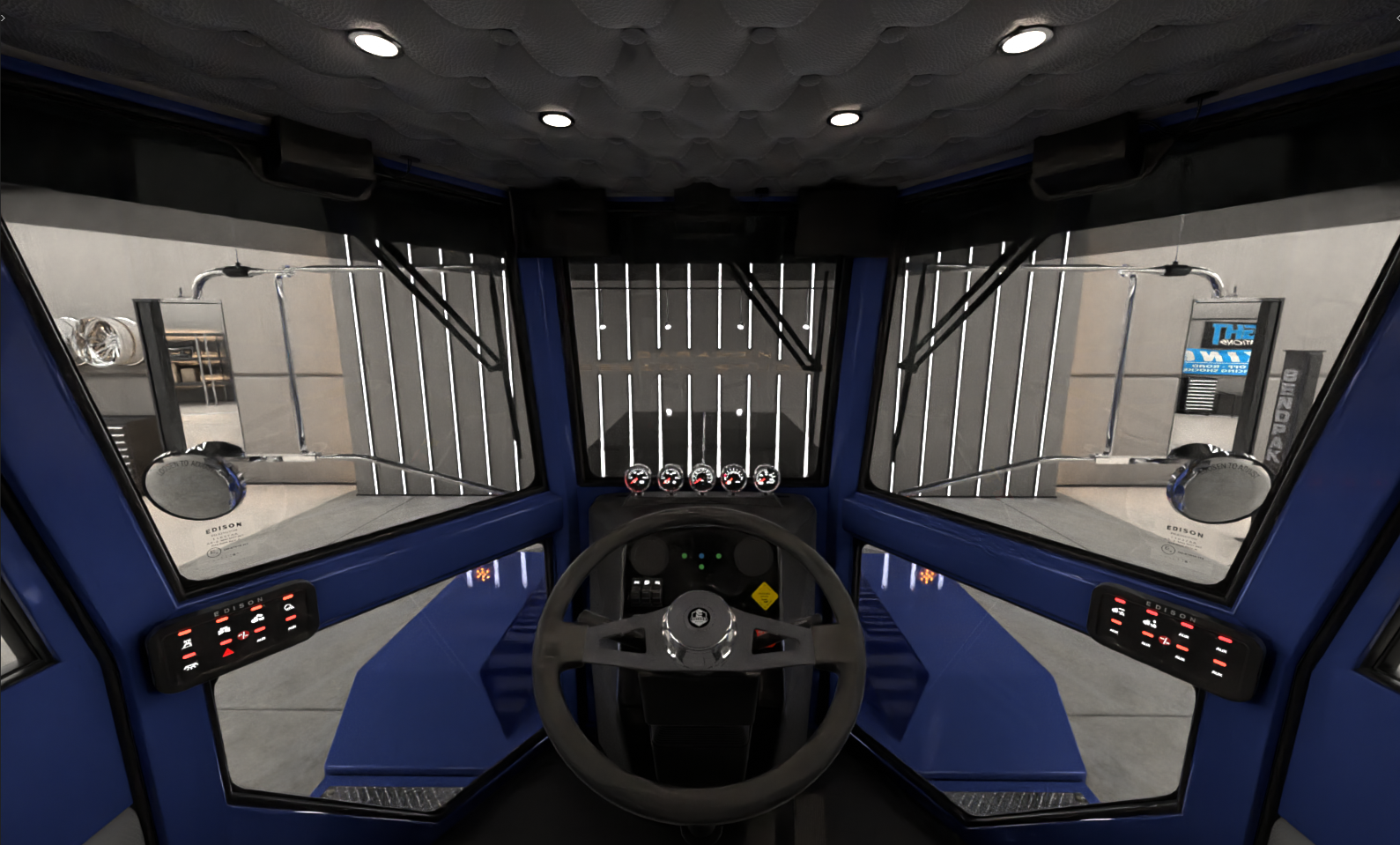

The L series Cab may be the toughest vocational cab ever made

The L Cab has a fully integrated steel, skidder, dozer style ROPS protection cage built into the cab. The truck cab shell is built around this steel cage for ultimate driver protection. The center seated driver position with the Dozer style cab also allows for increased visibility as the operator cab see both fenders from the drivers seat easily which makes maneuvering in tight spaces much easier.

The Dozer style cab also allows for a low entry approach angle, making entering the cab easier and safer for the driver. It also allows the easy cleaning of the front windshield without having to stand and reach over the steps leading to slipping hazard.

In vocational operations: the L-series can run 100% electric on the job site, resulting in lower noise pollution levels, allowing for increased levels of communication with workers on site.

The regenerative braking is up to 50% stronger than a traditional jake brake, giving unparalleled ability to slow the truck down safely.

No Planned obsolescence

Built to outlast

Our very ethos in starting this was to build a truck designed to last like our 1969 Kenworth or 1971 Pacific that’s hauled logs and equipment for over 50 years.

We have studied these old trucks to find out exactly how they can be running 50 years later and what it comes down to is that every part is easy to fix, easy to replace and designed as simply as possible.

We believe that you should only have to buy an L series Edison once.

If you’re worried that we’ll run out of customers to sell to: there’s 400,000 Vocational trucks made every single year, we don’t mind not having to replace the trucks we sell you.

Edison eV Energy Consulting:

PLANNING & SUPPORT

Edison engineers and sales team are experts in power systems, let us sit down, work with you and your bodybuilder and determine exactly what your power needs are and what the truck can do. We will work to figure out the best solution for your EV truck fleet.

This support goes beyond specing the trucks, we will work with your drivers, and mechanics to make sure the Edison electric truck integrates perfectly into your fleet.

Edison has in-house electricians to assess any charging infrastructure needs at your shop to make sure you can charge to your required level. Edison is able to install 3 phase power in a shop, we are unique in the EV manufacturing space in that aspect

Not only can we spec your truck for energy efficiency we can optimize the electrical efficiency of your shop as part of our whole package EV integration.